Hemp Fiber May Be A Viable Cotton-Compatible Textile Input

Hemp Fiber May Be A Viable Cotton-Compatible Textile Input

The hemp fiber industry holds tremendous economic potential. According to a recent market projection by MarkNtel Advisors, “the global hemp fiber market stood at USD 11 billion in 2024 and is projected to reach USD 36 billion by 2030, growing at a CAGR of 22%.”

“The surge in hemp fiber adoption reflects broader shifts in consumer behavior, policy frameworks, and material science innovation. Hemp’s fast growth rate, minimal pesticide requirements, and carbon sequestration properties are positioning it as a bio-based solution for climate-conscious industries.” MarkNtel Advisors stated.

One logistical issue that is holding the hemp fiber sector back, to some degree, is limited infrastructure. In the wider textile industry, hemp is largely seen as a niche material input requiring specialized machinery to create end products. However, a recent study is providing new insight into hemp’s potential as a cotton-compatible textile input.

A team of researchers affiliated with Universitat Politècnica de Catalunya-BarcelonaTech (Spain) and Dresden University of Technology (Germany) recently conducted a study examining non-textile hemp by using mechanical-chemical cottonization. The results of the study were published in the academic journal Cellulose.

“The raw material used was an agricultural residue that is mainly employed for paper manufacturing. These fibers were subjected to an alkaline chemical treatment followed by an oxidizing treatment (H2O2) to reduce non-cellulosic components.” the researchers stated about their methodology. “Subsequently, a mechanical process was carried out to increase fiber elementarization and obtain suitable slivers for spinning.”

“The potential of open-end rotor spinning was evaluated for both the 100% treated hemp and blends of 25% hemp/75% cotton. The selection criteria included a low reduction of the degree of cellulose polymerization, a low mass loss during the process, an appropriate tensile strength of the resulting yarns, an absence of breakage during spinning, and a low twist.” the researchers also wrote.

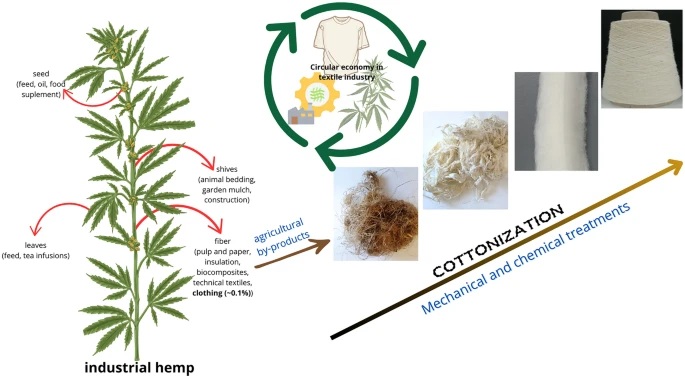

Below is a graphical abstract provided in the researchers’ article listed on Springer Nature:

“The hemp treated with a high level of H2O2 stabilizer, according to the established experimental design for the oxidizing process, exhibited superior performance when blended with cotton and spun with a count of 40 tex and a twist coefficient (αm) of 170. These outcomes are of industrial interest for the production of fine yarns because they can be easily implemented using existing machinery devoted to processing cotton.” the researchers determined.

“Furthermore, it contributes to the circular economy within the textile industry by adding value to a waste material that can serve as an alternative source of more environmentally friendly cellulosic fibers.” the researchers concluded.

The results of this recent study come at a time when Europe’s industrial hemp industry potential is being researched at an increasing rate. For example, a team of researchers affiliated with the University of Göttingen recently examined industrial hemp from the perspective of its prospects as a sustainable crop for modern agriculture in Germany.

“Industrial hemp offers promising prospects for agriculture. Its ecological advantages, such as improved soil structure and CO2 sequestration, as well as the economic potential offered by dual-use land and low or no need for pesticides, make it a sustainable addition to crop rotation.” the researchers concluded. “With the right strategy, industrial hemp can make a valuable contribution to sustainable agriculture, especially when economies of scale, stable sales contracts, and effective integration into crop rotation systems are considered.”

The University of Göttingen’s findings built on other recent hemp-focused sustainability research, including a study led by researchers affiliated with the University of Banja Luka, the University of Belgrade, and the University of Niš, which found that raw hemp can be used as an effective and eco-friendly alternative for removing toxic dye chemicals from wastewater.

During a recent presentation at the International Cannabis Business Conference in Berlin, leading international cannabis industry economist Beau Whitney, founder of Whitney Economics, provided data demonstrating that the value of the global industrial hemp industry could be as much as $456.2 billion.

Share article

Share article

Join Our Awesome Community

Join Our Awesome Community

Join Our Awesome

Community

Get all the latest industry news

delivered to your inbox